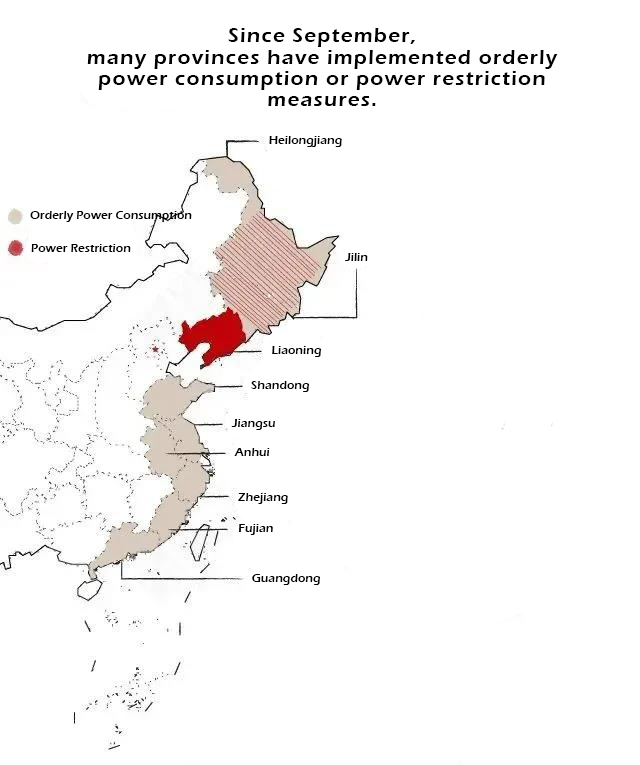

* * * * 2021 Power Restrictions

Recently, with the enacting of

dual control policy by NDRC, there have been 12 provinces having to limit their

power use for the reason of dual control of energy consumption and intensity,

insufficient power supply and environmental protection policy, which disturbed

their routine production.

Under the circumstances of normalized COVID-19, many enterprises have already been troubled by price-increasing raw material, with the issue of power restrictions, there comes another big problem of production, both of which struck them harder.

So, how to simultaneously ensure sufficient power use and energy-saving in all industries? The answer is backup energy storage power supply.

Backup

energy storage power supply is vital in the whole power value chain: on the one

hand, it can efficiently make use of energy; on the other hand, it can quickly

switch time to ensure constant power supply in all industry scenarios. Besides,

it can also avoid potential risks brought by oil transportation and storage of

traditional diesel generators.

No.1 Daily Check

FBR-600NT Internal Resistance Unit

FBR-600NT series unit can judge battery deterioration

quickly, intuitively and conveniently. It is featured with high accuracy, good

consistency of retest data and strong anti-interference performance. Clear and

intelligent display mode simplifies operation and portable design greatly

improves test efficiency, suitable for quick daily check of the energy storage

battery.

* Quick Test

Only probes contact needed in narrow space; real-time judgment; auto data storage; 2 seconds for every single test

* Strong Anti-interference Performance

Strong anti-interference performance; good consistency of retest data; stable and accurate measurement in battery test

even in serious ripple interference UPS machine room

* Data Processing

Powerful data processing ability; various kinds of test data charts can be shown on its screen and uploaded to cloud management

platform of batteries.

No.2 Periodic Maintenance

FGCD Series Battery Discharge-Charge Unit

FGCD series unit adopts advanced discharge-charge technology with a variety of built-in test and maintenance modes, plus its wide voltage range design(2-630V), it is suitable for regular check discharge test and capacity test of energy storage batteries. Comprehensive qualitative and quantitative tests and maintenance of energy storage battery performance can be realized.

* Discharge Test

Constant discharge can simulate a working state under battery load; constant power discharge can simulate actual battery load time.

* Charge Test

After discharging, the battery group can be directly charged. Scientific and efficient charging mode ensures the battery is fully

charged and undamaged.

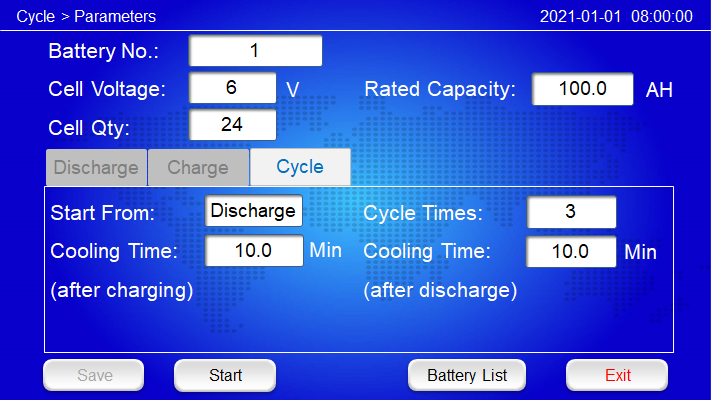

* Activation Test

If the capacity and performance of a battery group decrease, multiple times of discharge-charge cycles can be set to activate batteries so as to

improve the performance of the whole battery group.

No.3 Cell Activation

ABE-2612 Intelligent Cell Activation Unit

ABE-2612 can test capacity of lag batteries or charge them with low voltage and constant current according to the actual situation of batteries. Or setting multiple cycle periods to discharge and charge them to activate failure active substance of battery plate and promote capacity of them so that battery life can be extended. It can be applied in repairing capacity missing energy storage battery during check and test.

In addition to the above 3 on-site maintenance equipment, FUGUANG has independently researched and developed FBS-9600 battery online monitoring and remote automatic maintenance system to help energy storage users and battery manufacturers comprehensively grasp battery life cycle status through big data management. Efficient test and intelligent operation and maintenance protect the safe performance of backup energy storage power supply.

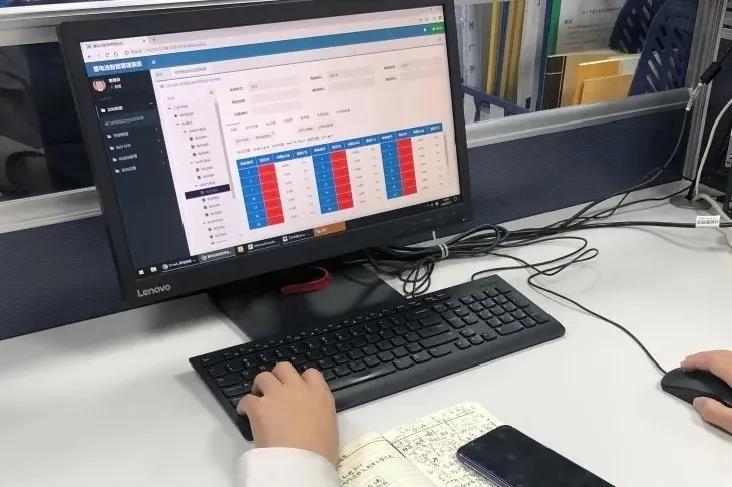

FBS-9600 battery online monitoring and remote automatic maintenance system

FBS-9600 adopts ‘1 drag 1’ distributed architecture to replace manual maintenance mode, and carries out remote monitoring and data collection for the battery group of the backup energy storage power supply. Comparison of battery history trends and peer comparison between cells in a battery group on a management platform can predict batteries with potential risk. With the assistance of the platform, battery group state repair and intelligent centralized management can be realized.

END

English

<

English

<

中文版

中文版